FOA 660 SDI

FOUR CYLINDER

ENDURANCE

HEAVY FUEL POWER

50 – 57 hp UAV engine, 660 cc four-opposed two-stroke, air-cooled.

Designed for large UAV platforms requiring continuous heavy-fuel performance.

![]() SWISS MADE

SWISS MADE

*under development juli 2026

The FOA 660-SDI marks Suter’s entry into the large UAV propulsion class.

With a four-cylinder opposed design, it delivers smooth, vibration-free performance and outstanding fuel efficiency, all within a compact and lightweight configuration.

Its heavy-fuel capability (kerosene based fuels like Jet-A1 / JP-5 / JP-8) and Swiss-engineered precision make it a proven solution for long-endurance, high-payload missions.

Civil Applications: Long-endurance surveillance UAVs, mapping platforms, twin-engine VTOL platforms.

Dual-Use Applications: Tactical and logistics UAV’s operating on Kerosine based fuels like Jet-A1 / JP-5 / JP-8 class.

KEY FEATURES

- Four-Cylinder Architecture

- Balanced operation with minimal vibration and long service intervals.

- Heavy-Fuel Operation

- Runs on gasoline and kerosene-based fuels such as Jet-A1, JP-5, JP-8 for unified logistics.

- Liquid-Cooled Design

- Stable power delivery under continuous or high-altitude load

- Swiss Engineering

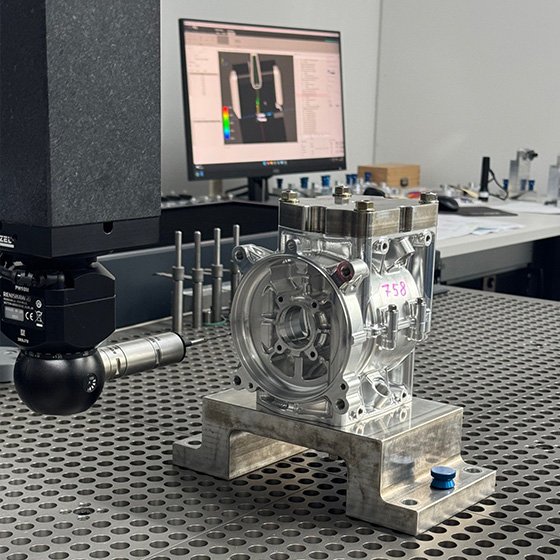

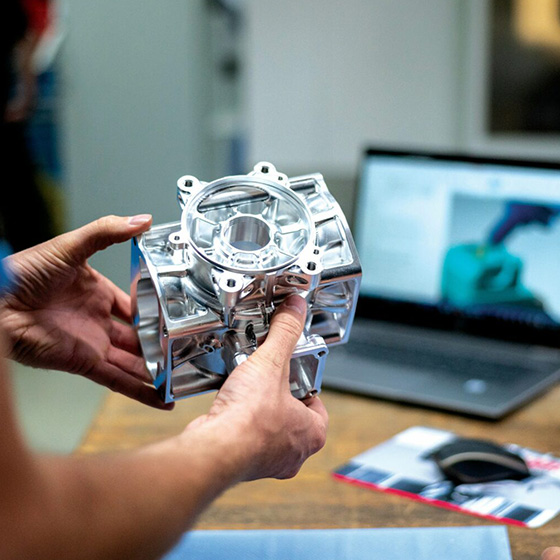

- Casted aluminium block, Nikasil cylinder coating, validated endurance performance.

TECHNICAL SPECIFICATIONS

FOA 660-SDI (Heavy Fuel, Liquid-Cooled)

| Parameter | Value |

|---|---|

| Fuel Efficiency | 305 g/kWh (BSFC) |

| Service Ceiling | 20,000 ft (6,100 m) |

| Displacement | 660 cc |

| Configuration | Four Opposed, Two-Stroke |

| Power Output | 37,0 – 42,0 kW (50,3 – 57,1 hp) at 6’750 rpm (HF – GAS) 55,0 – 63,5 Nm at 6’000 rpm (HF – GAS) |

| Weight | 16,7 kg engine* 2,4 kg exhaust & silencer 1,5 kg 1 kW/28VDC regulator 1,5 kg Generator 1 kW |

| Cooling | Air cooled |

| Fuel | gasoline and kerosine based fuels line Jet A-1, JP-5/JP-8 |

| Management & Control | ECU / 12V system, automatic |

| Ignition System | CDI (Capacitor Discharge Ignition) |

| Mixture | Direct Oil Injection, 2-stroke oil API TC |

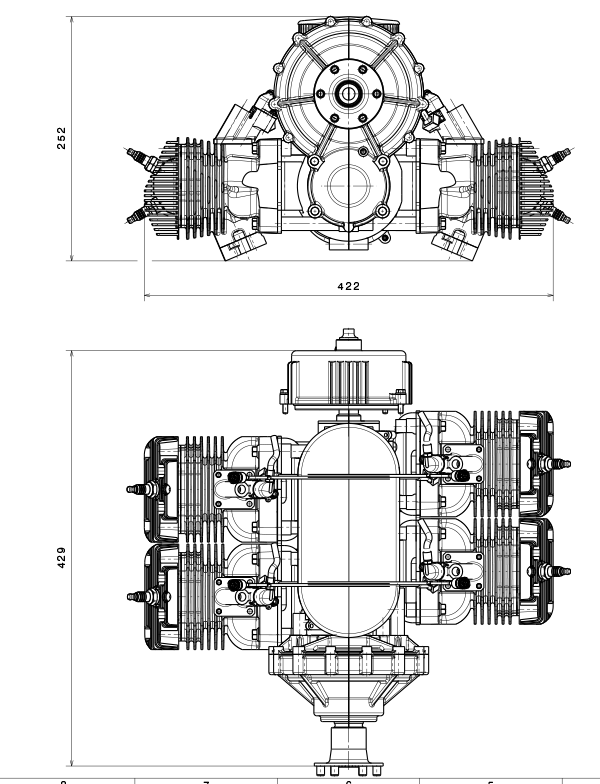

| Dimensions | 429 x 422 x 252 mm (L x W x H) |

UAV PROPULSION

ENGINEERING SOLUTIONS

Every engine has different integration needs to suit your aircraft. We offer integration engineering support for our engine packages. In addition to standard solutions we offer support to complete your firewall forward installation.

From servo controlled airducts, to keep engine temperature in the preferred range, or tailor-made engine mounts and optimized reduction drives, our engineers will support your demands. The package will be topped with our titanium exhaust systems, where engineering meets art.

Different aircraft and mission profiles and their specific mission profile eventually need an optimization of the engine fuel and ignition map, especially when the fuel varies from international standard specifications.

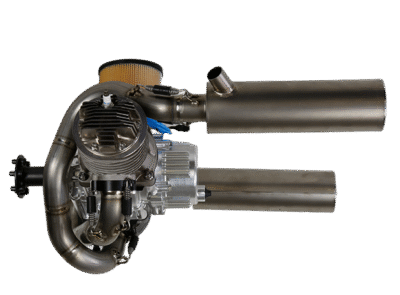

CUSTOM EXHAUST SYSTEM

Racing-proven titanium exhausts engineered for your UAV, powered by SUTER high-tech two stroke engine .

In two-stroke engines, the exhaust is not just an outlet.

It is an active part of the combustion cycle, directly influencing power, torque and efficiency.

Suter Titanium Exhaust Systems are designed to deliver optimized engine performance and high thermal durability. Built to withstand demanding operating environments, they provide repeatable performance and offers an unbeatable durability and weight.

KEY VALUE DRIVERS

- Performance-Tuned Exhaust Geometry

- Optimized expansion and flow characteristics support efficient combustion and consistent power delivery. Noise reduction included.

- Lightweight Titanium Construction

- Racing-derived titanium designs reduce system weight while maintaining strength and durability.

- Thermal Stability Under Continuous Load

- Engineered for sustained high-temperature operation without degradation in performance.

- Repeatable and Reliable Output

- Designed for consistent behavior across long mission durations and varying operating conditions.

WHY IT MATTERS

By treating the exhaust as a core engine component rather than an accessory, Suter improves combustion control, efficiency and overall system reliability.

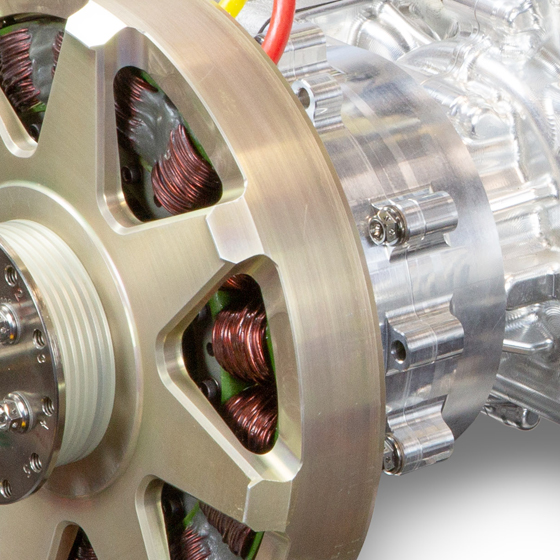

GENERATOR ADD-ON MODULE

Integrated electrical power for UAV systems that have a higher electrical power demand.

The Suter generator add-on module transforms a standard combustion engine into a fully integrated power unit.

It is engineered to provide continuous and stable electrical power for onboard systems, batteries and electric propulsion motors.

By integrating power generation directly into the engine architecture, the need for separate power units is reduced while improving overall system efficiency and reliability.

KEY VALUE DRIVERS

- Integrated Power Architecture

- Provides stable electrical output across changing load profiles, supporting all onboard electrical power demands.

- Lightweight and Efficient Design

- Minimizes impact on platform weight and endurance while maximizing usable electrical power.

- Scalable Configuration Options

- Adaptable to different propulsion layouts and mission requirements across UAV platforms.

- Thermal and Mechanical Stability

- Engineered for reliable operation during long-duration missions and demanding field conditions.

WHY IT MATTERS

Electrical availability directly defines mission capability. By integrating power generation at engine level, Suter enables higher operational autonomy, cleaner system architecture and predictable performance in the field.

MOUNTING FLEXIBILITY

Flexible installation for platform-specific integration.

All Suter engines are engineered for horizontal or vertical installation.

This flexibility reduces airframe adaptation needs and ensures compatibility across fixed-wing UAVs, rotorcraft and UGV platforms.

By offering adaptable mounting concepts, integration effort is reduced while maintaining structural integrity, vibration control and service accessibility.

KEY VALUE DRIVERS

- Horizontal and Vertical Installation Options

Supports clean integration across fixed-wing, rotary and ground-based platforms. - Reduced Airframe Adaptation

Minimizes structural modifications and shortens integration timelines. - Platform Compatibility

Ensures consistent mounting solutions across UAVs, rotorcraft and ground applications. - Structural Integrity and Accessibility

Engineered load paths and layouts support durability and ease of maintenance.

WHY IT MATTERS

Mounting flexibility directly impacts integration effort and long-term reliability.

By adapting the engine to the platform, Suter enables faster integration and predictable operational performance.

REDUCTION DRIVE

Optimized power delivery for propeller and rotor systems.

High-revving engines deliver maximum efficiency only when engine speed and propeller or rotor speed are correctly matched.

Suter Reduction Drives are engineered to translate engine output into usable thrust by balancing RPM, torque and mechanical loads.

By matching the engine’s operating range to the optimal propeller or rotor speed, reduction drives improve efficiency, reduce wear and support long-term operational reliability across UAV platforms.

KEY VALUE DRIVERS

- Optimized Gear Ratios

Precisely matched ratios ensure efficient power transfer from engine to propeller or rotor. - Improved Thrust Efficiency

Better propeller matching increases usable thrust and extends endurance. - Reduced Mechanical Stress

Lower rotational loads decrease vibration and wear on engine and drivetrain components. - Platform-Specific Configuration

Ratios and layouts can be tailored to match platform, mission profile and operating environment.

WHY IT MATTERS

Efficient power delivery is not about horsepower alone.

By optimizing the interface between engine and propeller or rotor, Suter Reduction Drives improve endurance, reliability and overall system performance.

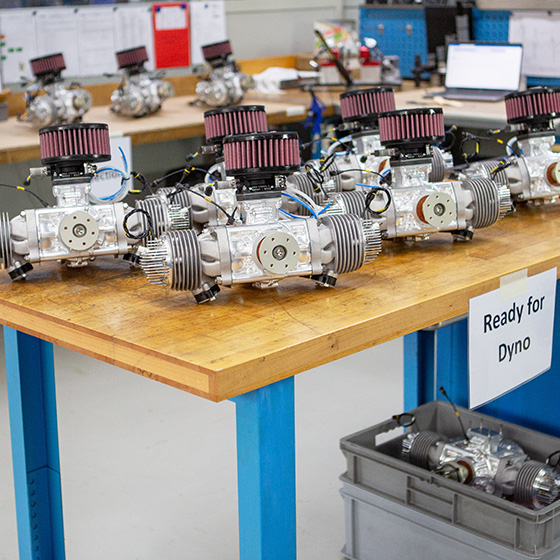

LIFECYCLELIFECYCLE SUPPORT

Sustained performance throughout the system lifecycle.

Integration does not stop at delivery.

Every Suter engine and system configuration is supported throughout its operational life to ensure reliability, availability and long-term value.

Lifecycle support is designed to maintain performance, simplify maintenance and allow controlled evolution of the system as mission requirements change.

KEY VALUE DRIVERS

- Documentation and Traceability

- Complete technical documentation, configuration records and revision control support safe operation and compliance.

- Spare Parts and Service Kits

- Structured spare parts availability and service kits ensure predictable maintenance and minimal downtime.

- Direct Engineering Access

- Customers have direct access to Suter’s engineering team for configuration support, troubleshooting and optimization.

- Upgrade and Optimization Pathways

- Software, control and hardware updates can be implemented to support evolving mission profiles.

WHY IT MATTERS

Operational reliability is built over time, not at delivery. By supporting systems throughout their lifecycle, Suter extends service life, protects performance and ensures long-term mission readiness.